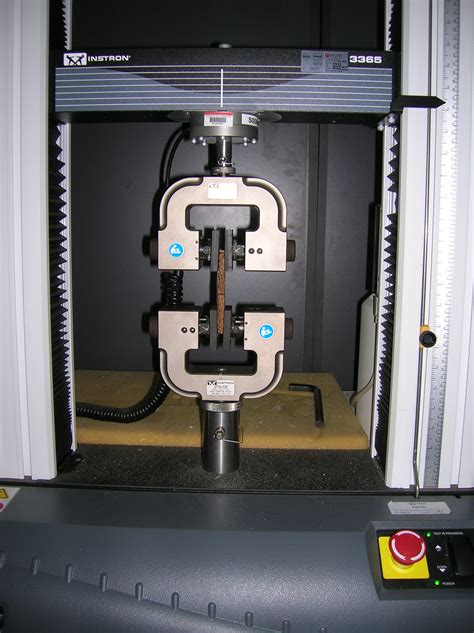

tensile strain testing machine|tensile testing tools : Brand The tensile test is conducted by use of a tensile testing machine or universal testing machine; the latter can be used for both tension and compression tests. In tensile testing, the specimen is firmly held in place by grips of the testing machine (see Fig. 3.4). One end of the specimen is held firm, whilst the other end is pulled by applying a .

Bem vindo ao nosso canal oficial no Youtubeyoutube.com/@amarelinhoitabunaEmail:

[email protected]: @amarelinhoitabuna

{plog:ftitle_list}

Entrega de alimentos perto de mim. O Restaurante Guru permite que você descubra ótimos lugares para comer perto da sua localização. Leia os cardápios dos .

Tensile testing machines are available in a variety of different sizes and force capacities ranging from 0.02 N to 2,000 kN. Most low force testing is performed on an electromechanical single .A tensile tester, also known as a pull tester or univeral testing machine (UTM), is an electromechanical test system that applies a tensile (pull) force to a material to determine the .The testing machine keeps the closed loop strain rate constant by using an extensometer to continuously provide strain values that are used to calculate the precise strain rate. . Tensile Testing Machine for High Test Loads From .

TestResources manufactures and supplies universal test machines, tensile testers, dynamic testing machines, and much more. Call us today (800)430-6536. . strain sensors needed for each test. Get started configuring your .

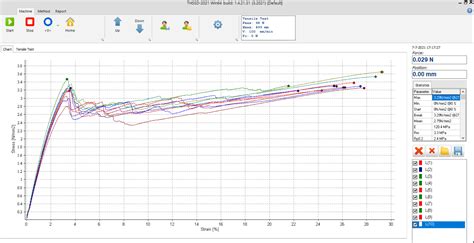

A tensile testing machine, often referred to as a universal testing machine (UTM), is an essential piece of equipment in material science.It is specifically designed to evaluate the tensile strength and other mechanical . The tensile test is conducted by use of a tensile testing machine or universal testing machine; the latter can be used for both tension and compression tests. In tensile testing, the specimen is firmly held in place by grips of the testing machine (see Fig. 3.4). One end of the specimen is held firm, whilst the other end is pulled by applying a . Tensile or tension testing is a fundamental and most commonly used test for the characterization of the mechanical behavior of materials. . Tensile testing is usually carried out in a testing machine at a materials testing laboratory. . Consider now that after a point in the plastic region of the stress–strain curve the applied tensile .

ADMET provides high-quality and reliable tensile test machines for a wide range of applications. Explore our tension testing equipment. Skip to content. Sales Inquiries (800) 667-3220 . These values are then presented on an XY plot called a stress-strain curve. Testing and measuring procedures vary based on the material being tested and its . Tensile testing machines work by grasping the test sample then applying a load until it deforms or breaks. Some examples of these machines are load cells, grips and extensometers. . Extensometers: Are used to measure change in length of the specimen which helps in determining strain; Test Speed: This is how quickly One applies stretching .strain diagram starting from a strain value of ε = 0.2% (or ε = 0.002). The yield stress is defined . The computerized tensile testing machine will be used to produce stress versus strain plots for several different specimens having rectangular .The standards applicable to tensile testing machines are the general standard DIN 51222, DIN EN ISO 6892-1 and DIN EN ISO 7500-1 for metallic materials and ISO 5893 for plastics and rubber. . DIN 50125 specifies which requirements apply to the materials of the tensile test specimen. For the failure strain, for some materials, the measurement .

ISO/CD 22183 project: Plastics – Determination of tensile properties at high rate using a servohydraulic testing machine; ISO 527-1, ISO 527-2; ASTM D638: Determination of tensile properties (covers only the area for low strain rates) SAE J2749 Nov 2008: High strain rate tensile testing of polymers; ISO 18872: Plastics – Determination of .

tensile testing tools

Exploring Elongation TestingElongation testing, a cornerstone of material science, reveals a material's ductility and strength when under tensile stress. By stretching a sample until it breaks, this test measures how much a material can deform before failing. In industries prioritizing safety and durability like automotive and construction, this insight is crucial. .A Universal Testing Machine (UTM), also known as a tensile testing machine/tester, is an electromechanical testing system that applies a tensile force to raw materials or components to test for both tensile and compressive strength. It is widely used for both small and large load testing in quality control or research projects, etc.

instron tensile compression tester model 4481

For this purpose the tensile test specimen is clamped in the universal testing machine and then the elongation ∆L is measured as a function of the tensile force F. . If the Young’s modulus of a material is determined by the tensile test, then the corresponding strain can be determined for each stress or, conversely, the required stress . As concerns of dynamic tensile measuring, a new tension mechanism driven by liner motor in high-speed tensile testing machine is presented. It satisfies the requirements for testing the dynamic tensile properties of plastic materials with strain rates from 1 to 100 s-1, which is relatively difficult to test for currently available machines.For this purpose the idle . Video 1: Tensile testing of annealed Cu sample (video and evolving nominal stress-strain plot) This page titled 5.5: Tensile Testing - Practical Basics is shared under a CC BY-NC-SA license and was authored, .

Tensile strengths of 2.0 to 5.0 mol% YâOâ-stabilized ZrOâ polycrystals are described using the newly developed tensile testing method. The tensile test was conducted by attaching three strain .Running the Tensile Test. Everything is in place, and it's time to rock 'n' roll! The following steps describe running the tensile test: (a) Start the Test. Hit the "Start" button on the control panel or software interface. At this moment, the UTM will begin pulling the specimen at the predetermined speed. (b) Monitor the TestStrain Measurement Some test methods require measurement of a specimen's elongation under load. Instron's AVE2 can measure changes to specimen length down to ±1 µm or 0.5% of reading. . Tensile testing machines are available in a variety of different sizes and force capacities ranging from 0.02 N to 2,000 kN. Most low force testing is .

tensile testing system

There are some practical difficulties in performing stress-strain tests in compression. If excessively large loads are mistakenly applied in a tensile test, perhaps by wrong settings on the testing machine, the specimen simply breaks and the .The tensile test is the most important and most frequently used mechanical-technological test worldwide, used to determine the strength and strain characteristic values for metals applications that are of crucial importance in the design and construction of components, commodities, machines, vehicles and buildings.. The test task is to determine material characteristic values .

The Comprehensive Materials Testing System includes everything needed to investigate compression and tensile testing, column buckling, three and four-point bending, shear testing, and stress lines with photoelasticity. . The Materials Testing Machine has a built-in load cell (strain gauge transducer) capable of measuring up to 7100 newtons (N . Discover TensileMill CNC's top universal testing machines designed for tensile testing. Find the UTM that meets your material testing needs. . Control Range: Stress rate from 1-60 MPa/S, with a strain rate adjustment range of 0.00025/S-0.0025/S. Displacement Rate: Adjustable between 0.5mm/min and 70mm/min.

a) Comparative stress-strain relationships of low carbon steel and aluminium alloy and b) the determination of the yield strength at 0.2% offset .3 Ultimate Tensile Strength, σ TS Beyond yielding .

Universal testing machines include electromechanical and hydraulic powered systems capable of performing static testing, . • Automatic Gain Adjustment Allows for closed loop strain control. . tensile, and flexure testing of devices or components with multiple test points or multiple components with repetitive test points.Tensile Testing Machine or Universal Testing Machine performs tensile, compression, flexion, shear tests, learn more. Home; Company; Products. Mechanical testing . One of the primary outputs of a tensile test is the stress-strain curve. This graph represents how a material responds to the applied stress, showing the relationship between the .

Extensometry is the science of the measurement and analysis of changes in a materials linear dimensions during tensile testing. . backlash or whiplash characteristics that could damage the testing equipment. . capability to more accurately determine strain and use strain as a control loop mechanism for test samples undergoing large . The tensile test procedure involves attaching the sample to the testing machine and applying force until the material fractures. The results are typically recorded in a stress-strain diagram. The most important parameters measured in the test are the ultimate tensile strength, yield strength, and elongation at break.

tensile testing software

instron tensile compression tester model 4481 diagrams

instron tensile compression tester model 4481 parts

7 de jul. de 2008 · Buy "Coronation Street": The Complete Saga: An Epic Novel of Life in 'the Street' from 1960 to the Present Day TV tie-in ed by Katherine Hardy, Glenda Young .

tensile strain testing machine|tensile testing tools